What is a thermocouple?

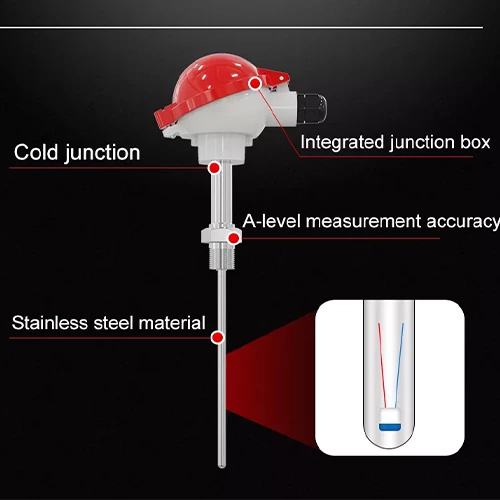

A thermocouple is a type of temperature sensor used in various industrial and scientific applications. It consists of two different metallic conductors joined together at one end, which are exposed to the temperature being measured at the other end. The difference in temperature between the two junctions generates a small voltage, which is then measured and converted into the corresponding temperature reading. Thermocouples are widely used because of their simplicity, low cost, wide temperature range, and durability. They are commonly used in HVAC systems, industrial processes, and scientific research.

What is the function of a thermocouple?

A thermocouple is a device that is used to measure temperature. It works based on the principle that when two dissimilar metals are joined at two different temperatures, a voltage is generated that is proportional to the temperature difference between the hot and cold junctions.

This voltage can be measured and used to determine the temperature. Thermocouples are commonly used in industrial applications such as furnaces, kilns, and boilers, as well as in scientific and laboratory settings.

They are relatively simple, low cost, and can measure a wide range of temperatures. However, they do have some drawbacks, such as a relatively low accuracy compared to other temperature sensors and a limited lifespan due to wear and tear.

Overall, thermocouples are a versatile and reliable temperature sensor that is widely used in many different applications.

Types of thermocouples

There are several types of thermocouples, which are classified based on the materials used to make them and their temperature range capabilities. Some of the most commonly used thermocouples are:

- Type K - made from nickel-chromium and nickel-aluminum, has a temperature range of -270°C to 1260°C, and is one of the most widely used thermocouples.

- Type J - made from iron and constantan, has a temperature range of -210°C to 1200°C, and is also widely used in industrial applications.

- Type T - made from copper and constantan, has a temperature range of -270°C to 400°C, and is commonly used in low-temperature applications.

- Type E - made from nickel-chromium and copper-nickel, has a temperature range of -270°C to 1000°C, and is commonly used in laboratory and research settings.

- Type N - made from nicrosil and nisil, has a temperature range of -270°C to 1300°C, and is commonly used in the aerospace and nuclear industries.

- Type S - made from platinum and platinum-rhodium, has a temperature range of 0°C to 1600°C, and is commonly used in high-temperature applications such as ceramics and glass manufacturing.

- Type R - made from platinum and platinum-rhodium, has a temperature range of 0°C to 1600°C, and is commonly used in high-temperature applications such as metalworking and heat treating.

Other less commonly used types of thermocouples include B, C and D types, each with their specific range of temperature measurement.

RTD vs. Thermocouple

A Resistance Temperature Detector (RTD) and a thermocouple are two types of temperature sensors.

The main difference between an RTD and a thermocouple is the way they measure temperature. An RTD measures temperature by using the principle of electrical resistance, while a thermocouple measures temperature by using the principle of thermoelectricity.

An RTD is typically made of a metal, such as platinum, copper, or nickel, which has a positive temperature coefficient of resistance (PTCR). This means that as the temperature of the metal increases, the electrical resistance of the metal also increases. The change in resistance can be measured and used to calculate the temperature.

A thermocouple, on the other hand, is made of two different metals that are joined together at one end. When the temperature at the junction of the two metals changes, a voltage is generated that is proportional to the temperature difference between the junction and the other end of the thermocouple. This voltage can be measured and used to calculate the temperature.

Both RTDs and thermocouples have their advantages and disadvantages. RTDs are known for their high accuracy and stability, but they are more expensive than thermocouples and are limited in their temperature range. Thermocouples, on the other hand, are less expensive than RTDs and can measure a wider range of temperatures, but they are less accurate and can be affected by electromagnetic interference.

Ultimately, the choice between an RTD and a thermocouple depends on the specific application and its requirements for accuracy, temperature range, and cost.

How to Choose a thermocouple?

Choosing the right thermocouple for your application depends on several factors including the temperature range, accuracy, environment, and budget. Here are some factors to consider when selecting a thermocouple:

- Temperature range: Make sure the thermocouple you choose can measure temperatures within your required range. Each type of thermocouple has a different temperature range capability, so it is important to select one that fits your needs.

- Accuracy: Depending on the application, you may need a thermocouple with higher accuracy. Make sure to choose a thermocouple that meets the accuracy requirements of your application.

- Environment: Consider the environment in which the thermocouple will be used. Will it be exposed to moisture, corrosive chemicals, or other harsh conditions? Make sure to choose a thermocouple that is suitable for the specific environment in which it will be used.

- Response time: Depending on your application, you may need a thermocouple with a fast response time or a slower response time. Make sure to choose a thermocouple that meets the response time requirements of your application.

- Cost: Thermocouples vary in price, depending on the type and features. Consider the budget for your application and choose a thermocouple that meets your needs without exceeding your budget.

- Overall, it is important to carefully evaluate your application’s requirements and choose a thermocouple that meets those requirements while staying within your budget.

Thermocouple probes vs. Thermocouple wire

Thermocouple probes and thermocouple wire are both used for temperature measurement in various industrial and scientific applications. Here are some differences between the two:

- Thermocouple wire is just the bare wire, without any additional components, while thermocouple probes have a metal casing that protects the wire and allows for easy insertion into the measurement area.

- Thermocouple wire can be purchased in various lengths, while thermocouple probes are typically sold as a complete unit.

- Thermocouple wire can be more versatile than probes since it can be cut to a specific length and used with different types of connectors and instruments.

- Thermocouple probes are typically more durable than wire and can withstand harsh environments.

- Thermocouple probes can be more accurate than wire since they are designed to be used in specific applications and can be calibrated accordingly.