What is a pressure sensor?

A pressure sensor is a device that measures the pressure of gases or liquids and converts the measured pressure into an electrical signal that can be read by an instrument or controller. Pressure sensors are commonly used in a wide range of applications, including industrial automation, medical equipment, automotive systems, and environmental monitoring.

Pressure sensors work by using a transducer to detect changes in pressure and convert them into a corresponding electrical signal.

There are several types of pressure sensors, including piezoresistive sensors, capacitive sensors, and optical sensors, each of which uses a different mechanism to detect pressure.

Piezoresistive sensors, for example, use a small diaphragm that deforms in response to changes in pressure, causing a change in resistance that can be measured. Capacitive sensors, on the other hand, use two plates separated by a small gap, with the distance between the plates changing in response to pressure, causing a change in capacitance that can be measured. Optical sensors use a light source and a detector to measure changes in pressure based on changes in the refractive index of a fluid.

Pressure sensors are an important tool for measuring and monitoring pressure in a wide range of applications.

What is a pressure transmitter?

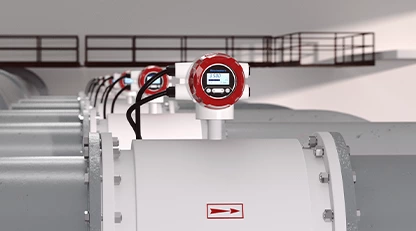

A pressure transmitter is a type of pressure sensor that measures the pressure of gases or liquids and transmits the measured pressure to a control system or instrument through an electrical signal. Pressure transmitters are commonly used in industrial applications, such as process control, oil and gas production, and manufacturing, where accurate and reliable pressure measurements are critical.

The basic principle of a pressure transmitter is similar to that of a pressure sensor. It uses a sensing element, such as a piezoresistive or capacitive sensor, to detect changes in pressure and convert them into a corresponding electrical signal. However, unlike a simple pressure sensor, a pressure transmitter includes additional electronics that amplify, filter, and condition the signal before transmitting it to a control system or instrument.

Pressure transmitters typically include a range of features, such as the ability to adjust the output signal, calibration and diagnostic tools, and protection against environmental factors like temperature and humidity. They may also be designed to operate in hazardous environments and meet various international standards for safety and performance.

Pressure transmitters are a critical component of many industrial processes and systems, providing accurate and reliable measurements of pressure that are used to monitor and control operations and ensure the safety and efficiency of operations.

What is a pressure transducer?

A pressure transducer is a device that converts pressure into an electrical signal. It is a type of pressure sensor that can be used to measure the pressure of gases or liquids in a wide range of applications, including industrial automation, automotive systems, aerospace, and medical equipment.

Pressure transducers work on the principle of piezoelectricity or piezoresistivity. Piezoelectric pressure transducers use a crystal or ceramic material that generates an electrical charge when pressure is applied, while piezoresistive pressure transducers use a material whose resistance changes when pressure is applied. In both cases, the applied pressure causes a mechanical deformation in the sensing element, which is then converted into an electrical signal proportional to the pressure.

Pressure transducers can be designed to measure absolute pressure, gauge pressure, differential pressure, or vacuum pressure. They can also be designed to measure pressure in various units, such as psi, bar, or Pascal.

Pressure transducers are often used in conjunction with instrumentation or control systems, where the electrical signal generated by the transducer can be processed and analyzed. They can be used in closed-loop control systems, where they help maintain a desired pressure level by adjusting control valves, pumps, or other equipment. They can also be used for monitoring and data acquisition in various industrial and scientific applications.

Pressure transducers are a vital component in many industries and applications, providing accurate and reliable pressure measurements that help ensure the safety and efficiency of operations.

What is a pressure switch?

A pressure switch is a type of switch that activates or deactivates an electrical circuit based on changes in pressure. Pressure switches are commonly used in various applications, such as industrial automation, HVAC systems, and process control, where they provide a simple and effective way to monitor and control pressure levels.

A pressure switch typically consists of a sensing element, a switch mechanism, and a housing. The sensing element is designed to detect changes in pressure and generate a corresponding mechanical force, which is then used to actuate the switch mechanism. The switch mechanism can be either mechanical or electrical, and it is designed to open or close the electrical circuit when the pressure reaches a specific set point.

Pressure switches can be designed to operate in various pressure ranges and with different pressure media, such as air, water, oil, or gas. They can also be designed to measure absolute pressure, gauge pressure, differential pressure, or vacuum pressure.

Pressure switches are often used in safety-critical applications, such as to detect overpressure or underpressure conditions in a system and trigger alarms or shut down the system to prevent damage or injury. They can also be used in process control applications to monitor and regulate pressure levels to ensure optimal performance and efficiency.

Overall, pressure switches are an essential component in many industrial and commercial applications, providing a cost-effective and reliable way to monitor and control pressure levels.

What is the difference between pressure sensors and pressure transmitters?

Pressure sensors and pressure transmitters are both devices used to measure pressure, but there are some key differences between the two.

A pressure sensor is a device that measures the pressure of gases or liquids and converts the measured pressure into an electrical signal. It is typically a stand-alone device that provides an output signal proportional to the measured pressure. Pressure sensors are often used in research and development, testing, and monitoring applications, where the measured pressure is not critical to the operation of a system.

A pressure transmitter, on the other hand, is a device that also measures the pressure of gases or liquids and converts it into an electrical signal, but it goes a step further by transmitting that signal to a control system or instrument. Pressure transmitters are typically integrated into a system or process, and they provide a continuous and accurate measurement of pressure that is used to monitor and control the operation of the system.

Another difference between pressure sensors and pressure transmitters is their level of accuracy and stability. Pressure transmitters are often designed to provide a highly accurate and stable measurement of pressure, whereas pressure sensors may have lower accuracy or stability.

While pressure sensors and pressure transmitters have some similarities in terms of their basic function, they differ in terms of their integration into systems, their level of accuracy and stability, and their use cases.

What’s the difference between pressure sensors and pressure transducers?

The term pressure sensor and pressure transducer are often used interchangeably, and in many cases, they refer to the same device. However, there are some differences between the two, depending on the context in which they are used.

In general, a pressure sensor is a device that detects changes in pressure and converts them into an electrical signal. It can be used to measure various types of pressure, such as gauge pressure, absolute pressure, or differential pressure. A pressure sensor can be a standalone device or part of a larger system.

On the other hand, a pressure transducer is a specific type of pressure sensor that converts changes in pressure into a proportional electrical signal, typically a voltage or current. Pressure transducers are often used in industrial applications and are designed to provide accurate and reliable pressure measurements in harsh environments.

The main difference between pressure sensors and pressure transducers is that pressure transducers typically provide an electrical output signal that can be used by other electronic devices, such as control systems, computers, or data loggers. Pressure sensors may or may not provide an electrical output signal, depending on their specific design and application.

Overall, while pressure sensors and pressure transducers are similar devices, pressure transducers typically have more specialized applications and are often used in industrial and scientific settings where precise and reliable pressure measurements are critical.

What is the difference between a pressure switch and a pressure transmitter?

The main difference between a pressure switch and a pressure transmitter is in their function and operation.

A pressure switch is a mechanical device that is designed to detect changes in pressure and activate or deactivate an electrical circuit based on a predetermined set point. Pressure switches are typically used in simple control applications, such as to turn on or off a pump or compressor when the pressure reaches a certain level.

On the other hand, a pressure transmitter is an electronic device that is designed to measure the pressure of a fluid or gas and convert it into an electrical signal, which is then transmitted to a control system or computer for monitoring and analysis. Pressure transmitters are often used in complex industrial applications, where precise and accurate pressure measurements are required to ensure optimal performance and safety.

Another key difference between pressure switches and pressure transmitters is in their accuracy and range. Pressure switches are typically designed to operate within a narrow pressure range and have a limited accuracy. Pressure transmitters, on the other hand, can measure pressure over a wide range and with high accuracy, making them suitable for more demanding applications.

Overall, while pressure switches and pressure transmitters both serve the purpose of measuring pressure, they have different applications and functions. Pressure switches are simpler devices that are used for basic control purposes, while pressure transmitters are more complex devices that are used for monitoring and control in advanced industrial processes.

Sino-measure pressure sensor & transmitter & transducer

Sino-measure is a pressure sensor & transmitter & transducer supplier, located in China. We offer various pressure sensors & transmitters & transducers, at competitive prices. A wide range of pressure transmitters is available to you. The options include Pressure and temperature transmitter, 2088 Membrane pressure transmitter, Hygienic pressure transmitter, High-temperature pressure transmitter, Pressure transmitter with display, and so forth.

Please do not hesitate to contact us if you have any questions about pressure sensors & transmitters & transducers. Send an inquiry now and we will get back to you in less than 20 hours.