Introduction

An oval gear flow transmitter is a type of positive displacement flow meter that measures the flow rate of liquids. It consists of two oval-shaped gears placed within a chamber or housing. These gears rotate as the fluid passes through the meter, and the rotation is directly proportional to the volume of liquid flowing through the meter.

One of the advantages of an oval gear flow transmitter is its accuracy. It can measure flow rates with high precision, making it suitable for applications where precise measurements are required. It is also a reliable device that can operate in harsh environments, such as those with high temperatures or pressures.

Another benefit of an oval gear flow transmitter is its versatility. It can be used to measure the flow rate of a wide range of fluids, including liquids and gases. It is also compatible with different types of pipes, such as steel, plastic, or copper.

Working Principle

The working principle of an oval gear flow transmitter is based on the movement of the oval gears. As the liquid flows through the meter, it enters the chamber and pushes the gears. The gears rotate as the liquid moves, creating a precise measurement of the flow rate. The rotation of the gears is detected by sensors or magnets, which generate electrical signals proportional to the flow rate.

Features

- Resistant to high pressure (1.0-45MPa)

- High and low temperature resistance (-196℃-200℃)

- Various viscous media can be measured

- High precision and high repeatability

- Pulse output/analog output is optional

- Range specific width (1:100)

- Wide measuring range

- Strong anti-corrosion and anti-fouling ability (acid and alkali)

Parameters

| Model | Range 1/H | K coefficient P/L | Max pressure | Temp | Accuracy | Connection | |

| Aluminium alloy | Stainless stee | ||||||

| GF02 | 0.6-50 | 11200 | 150 | 400 | -15~80℃ | ±0.5% (Range ratio 1:10) ±1.0% (Range ratio 1:100) | G1/ |

| GF04 | 5-250 | 4780 | 150 | 400 | -15~80℃ | G3/8 | |

| GF06 | 10-500 | 3468 | 150 | 400 | -15~80℃ | G1/2 | |

| GF10 | 50-1200 | 2780 | 150 | 400 | -15~80℃ | G1/2 | |

| GF15 | 200-3000 | 334 | 150 | 400 | -15~80℃ | G3/4 | |

| GF25 | 1000-12000 | 59.9 | 150 | 400 | -15~80℃ | G1 | |

| GF32 | 2000-20000 | 39.9 | 150 | 400 | -15~80℃ | G1-1/4 | |

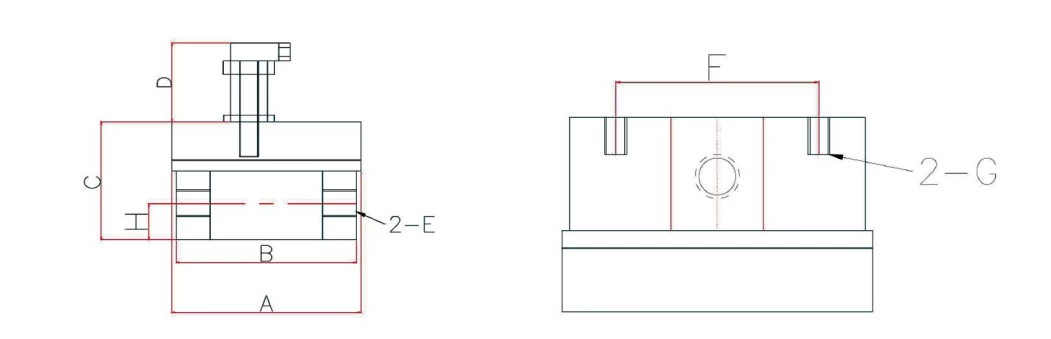

Dimension

unit: mm

| A | B | C | D | E | F | G | H | |

| GF02 | Φ83 | 80 | 55 | 70 | G1/4 | 40 | M6 | 16 |

| GF04 | Φ83 | 80 | 55 | 70 | G3/8 | 55 | M6 | 16 |

| GF06 | Φ83 | 80 | 62 | 70 | G1/2 | 55 | M6 | 14 |

| GF10 | Φ83 | 80 | 65 | 70 | G1/2 | 55 | M6 | 14 |

| GF15 | Φ113 | 110 | 65 | 70 | G3/4 | 90 | M6 | 28 |

| GF25 | Φ158 | 140 | 85 | 70 | G1 | 110 | M6 | 40 |

| GF32 | Φ218 | 160 | 100 | 70 | G1-1/4 | 180 | M6 | 45 |

Other sizes can be customized.