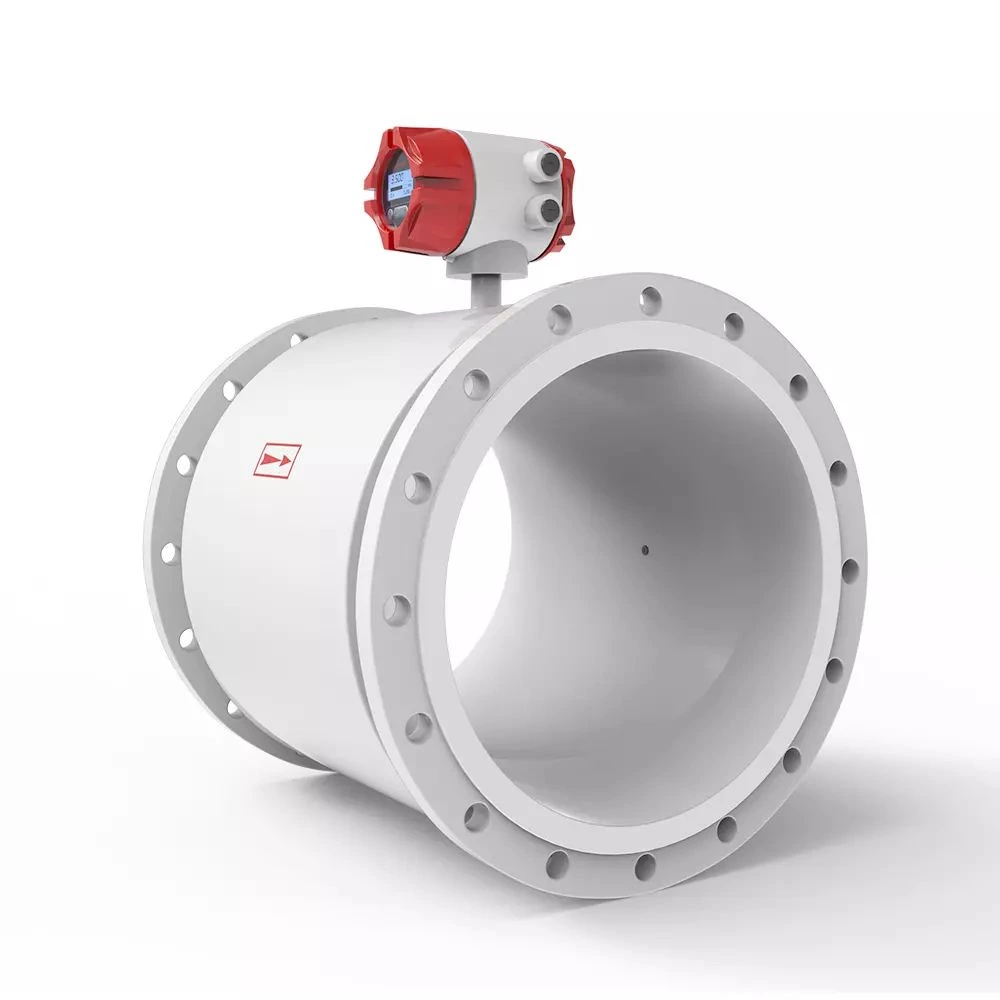

SIN-LDG Electromagnetic flowmeter for sewage treatment

Pipe diameter: DN15~DN1000

Accuracy: ±0.5%(Flow speed > 1m/s)

Electric conductivity: Water: Min. 20μS/cm; Other liquid: Min. 5μS/cm

Turndown ratio: 1:100

Power supply: 100-240VAC,50/60Hz; 22-26VDC

Minimal Maintainice. Has no moving parts or flow obstructiions, which virtually eliminates maintenance and pressure drops

-

Specification

| Product | Electromagnetic flow meter |

| Model | SIN-LDG |

| Diameter nominal | DN15~DN1200 |

| Nominal pressure | DN15 - DN250, PN ≤1.6MPa |

| DN300 - DN1000, PN ≤1.0MPa | |

| DN1200, PN ≤0.6 MPa | |

| Higher pressure can be customized | |

| Accuracy | ±0.5% F.S. (Flow speed > 1m/s); ±0.5% F.S.±2mm/s (Flow speed <1m/s) |

| Repetitiveness | 0.16% |

| Liner material | Neoprene (CR), Polyurethane (PU), PTFE (F4), PFEP (F46), PFA |

| Electrode material | 316L Stainless Steel, Hastelloy C, Hastelloy B, Ti, Ta, Pt |

| Medium temperature | Neoprene: -10…+60℃ Polyurethane: -10…+60℃ PTFE/FEP: -10…+120℃ PFA: -10…+120℃ |

| Power supply | 85-245VAC,50/60Hz, 22VDC-26VDC |

| Structure type | Compact type, Remote type |

| Ingress protection | IP65, IP68(remote type only) |

| Product standard | JB/T 9248-2015 |

-

Magnetic flow meter installation

Here are some general guidelines for installing a magnetic flow meter:

Pipe diameter: Select a flow meter that is appropriate for the pipe diameter. The flow meter should fit the size of the pipe and should be installed at the correct orientation.

Straight pipe runs: The flow meter should be installed in a section of pipe that has a straight run of at least 5 pipe diameters upstream of the meter and 2 pipe diameters downstream of the meter.

Positioning: Install the flow meter in a horizontal pipe, with the flow going from the larger diameter section to the smaller diameter section. If installed vertically, the flow must be upward.

Inlet and outlet conditions: Ensure that the inlet and outlet piping are straight, with no obstructions or bends in the piping near the meter. The flow should be fully developed, without any swirl or turbulence, and the pipe should be level to prevent air pockets from forming.

Grounding: Magnetic flow meters require grounding to eliminate electrical noise and ensure accurate readings. Proper grounding is essential for the operation of the meter.

Electrical connections: Connect the electrical leads to the appropriate terminals and ensure that the wiring is correct.

Material compatibility: The materials used for the flow meter and the piping should be compatible with the fluid being measured.

Calibration: Magnetic flow meters require calibration to ensure accurate measurements. Calibration should be performed according to the manufacturer's recommendations and should be repeated periodically.

It is important to consult with the manufacturer's specific installation guidelines and work with an experienced engineer to ensure proper installation and accurate measurement of fluid flow.

-

Description