HART Protocol Guide: Smart Instrumentation for Modern Industry

Essential Technology for Hybrid Analog-Digital Systems

Why HART Matters in Industry 4.0

Bridging legacy 4-20mA systems with digital automation, HART protocol remains vital for process control. This guide covers implementation best practices and technical specifications.

Hybrid Communication

- Analog 4-20mA + Digital FSK

- Simultaneous process & diagnostic data

- Backward compatible design

Technical Specifications

- 230-1100Ω loop resistance

- 3000m maximum cable length

- 15 devices per network

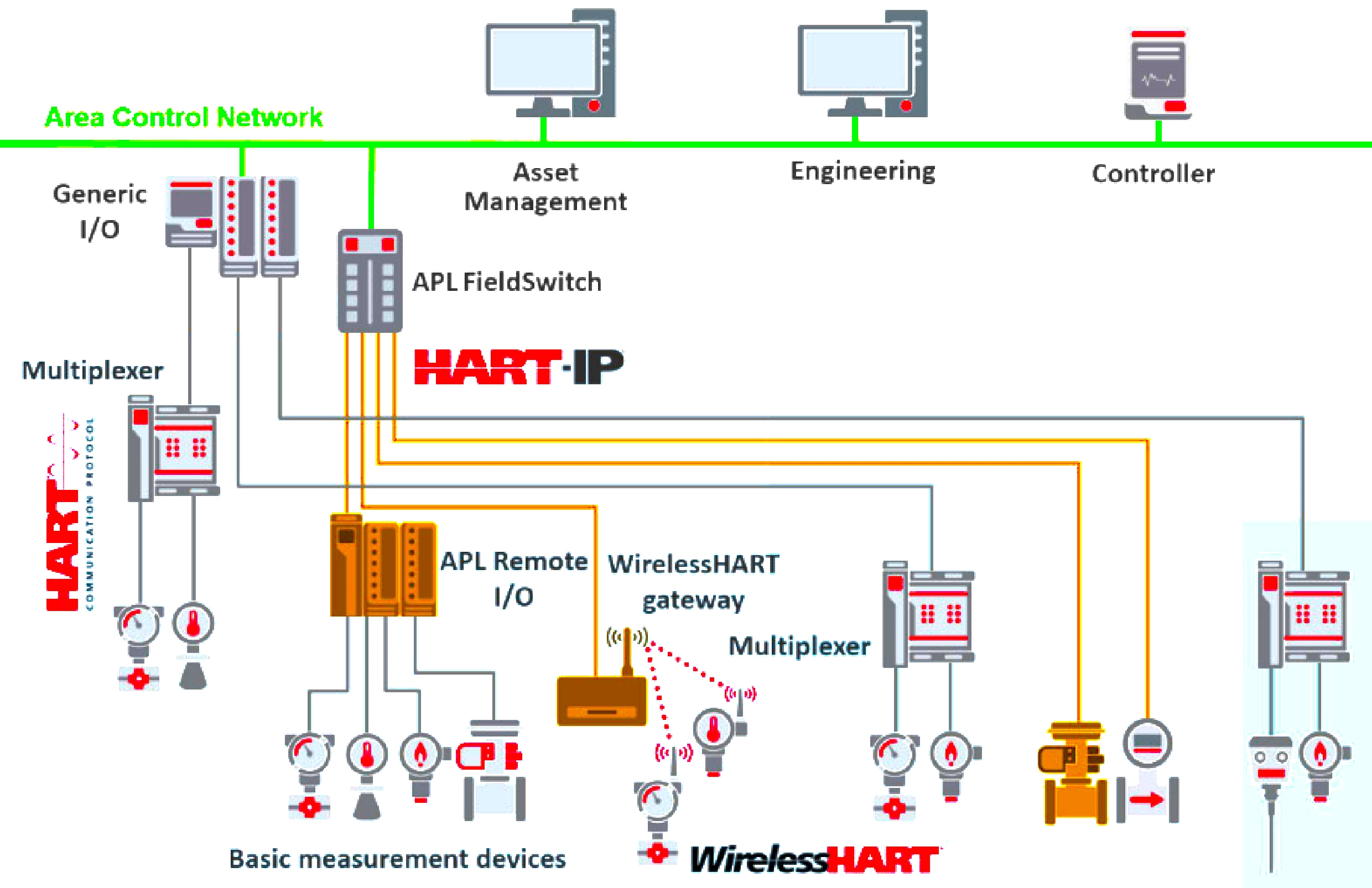

System Architecture Components

Master Devices

PLCs, DCS, handheld communicators

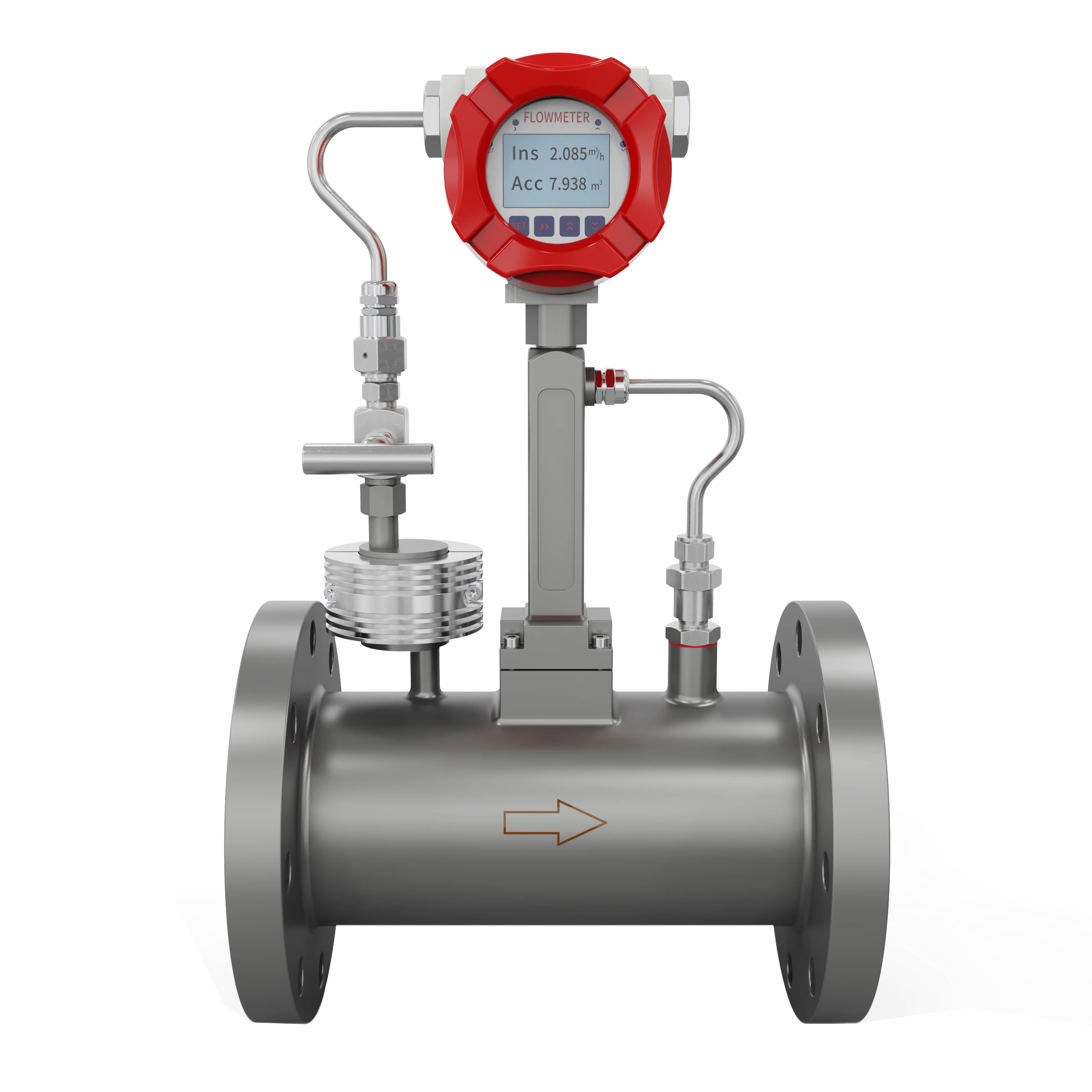

Field Devices

Transmitters, sensors, control valves

Practical Implementations

Real-time Device Configuration

Instant parameter adjustment and monitoring for optimal performance

Predictive Maintenance Alerts

Advanced analytics to prevent downtime before it occurs

Multi-variable Transmission

Simultaneous data streams for comprehensive process insights

Operational Advantages

Reduced Wiring

Multi-drop capability minimizes installation complexity

Enhanced Diagnostics

Real-time device health monitoring and alerts

Vendor Neutral

Seamless integration across multiple equipment brands