Large-Diameter Electromagnetic Flowmeters

Large-diameter electromagnetic flowmeters are vital for managing high-volume water and wastewater systems. Utility companies rely on these devices for precise flow measurement in applications like water treatment plants and urban sewage networks. This guide helps you select the right manufacturer, understand installation requirements, and choose the optimal flowmeter type for your project.

Key Features of Large-Diameter Flowmeters

- Accurate flow measurement in high-capacity systems

- Robust design for harsh environmental conditions

- Compatibility with conductive liquids (e.g., water, wastewater)

Types of Large-Diameter Flowmeters

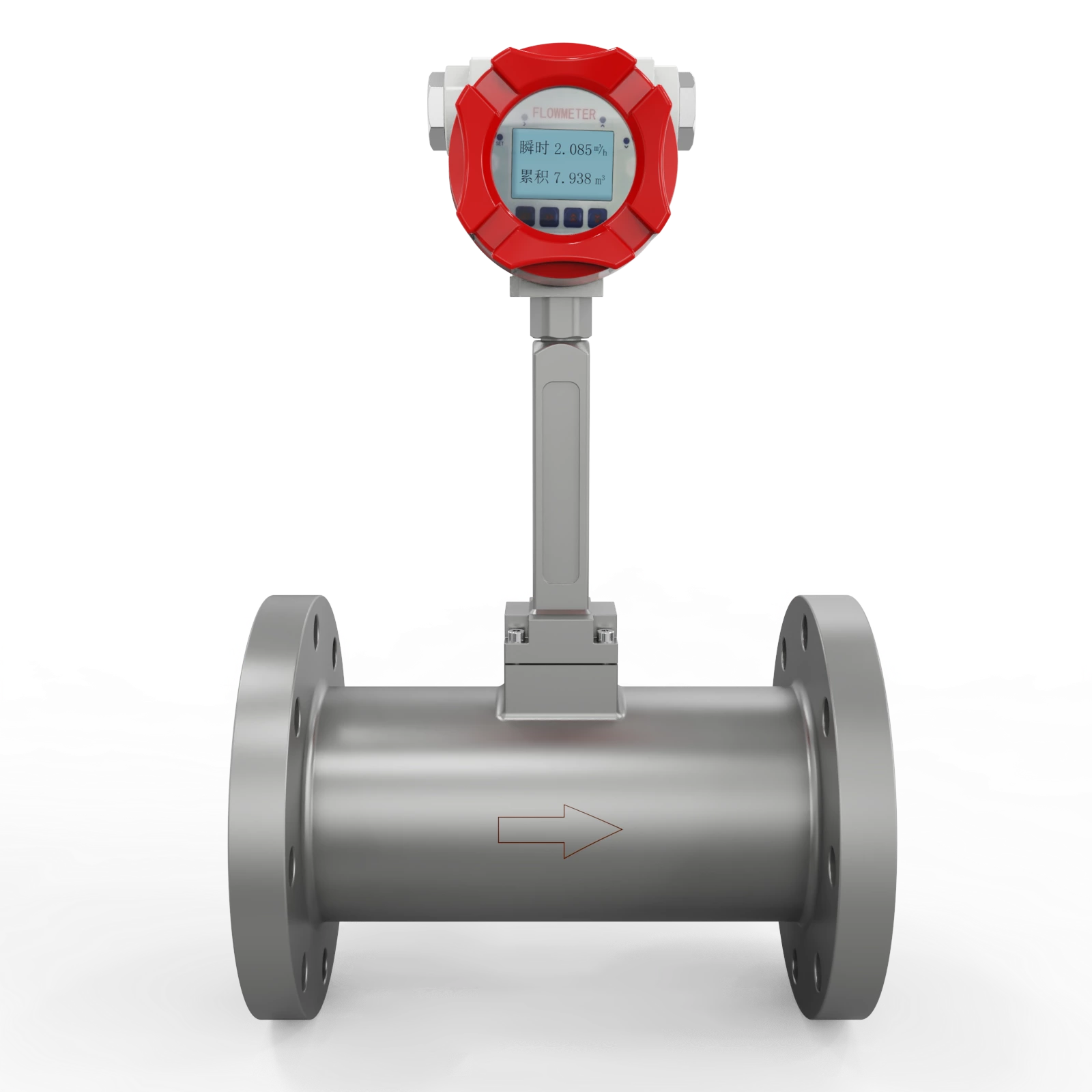

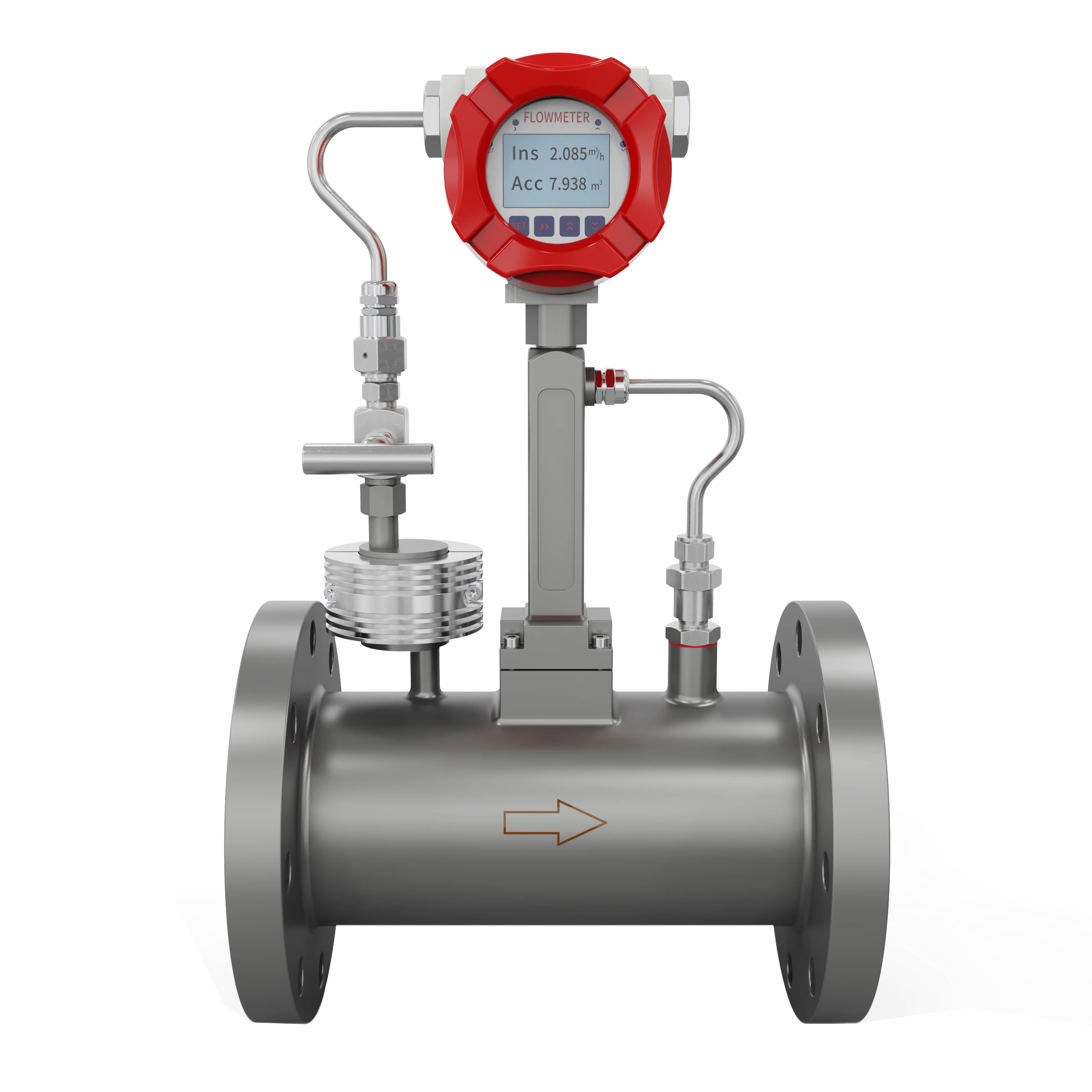

2.1 Insertion-Type Flowmeters

Ideal for large-diameter pipelines due to:

- Lower installation costs compared to flange-mounted systems

- Quick installation without full pipeline shutdown

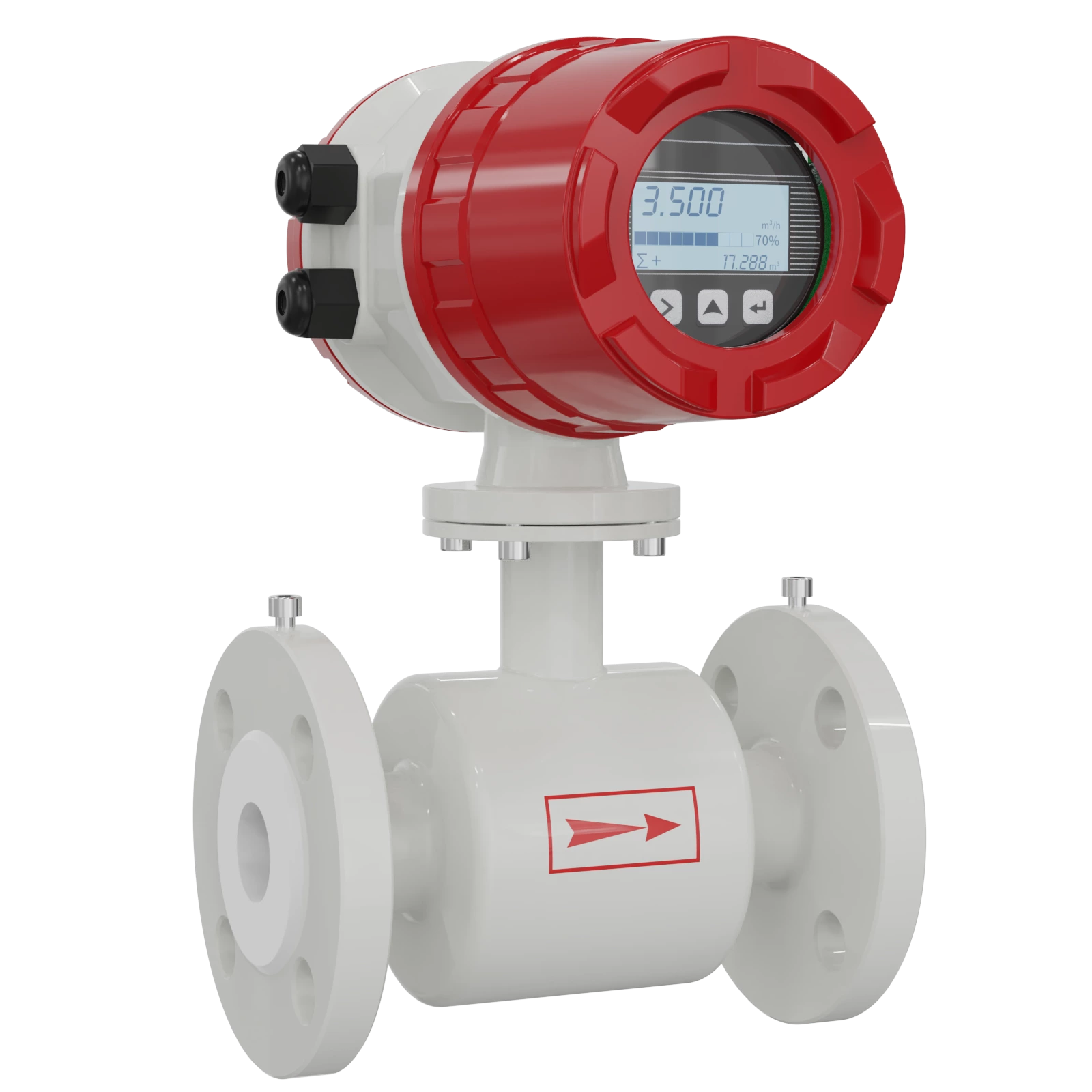

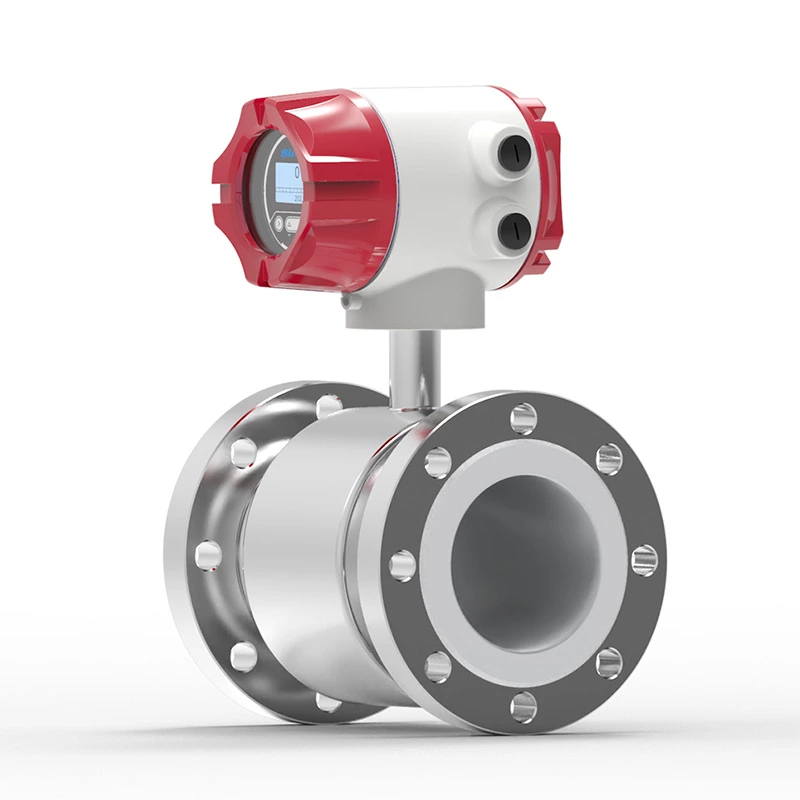

2.2 Flange-Mounted Flowmeters

Superior for precision applications:

- Three-electrode design for accuracy (±0.5-1%)

- Best for stable flow conditions requiring minimal turbulence

Key Advantages

- No moving parts → minimal maintenance and pressure loss

- Stable measurements unaffected by temperature, viscosity, or density changes

- Wide range ratio (1:100) for precise flow tracking

Installation Guidelines

4.1 Straight Pipe Requirements

- Upstream: Minimum 10 × DN straight pipe

- Downstream: Minimum 5 × DN straight pipe

4.2 Medium Requirements

- Fluid conductivity ≥5 μS/cm

- Minimal solid particles (≤2% by volume)

Choosing a Reputable Manufacturer

Sinomeasure provides:

- Deployed in major projects like Hangzhou Qige Wastewater Plant

- ISO 9001-certified quality assurance

- 24/7 technical support hotline: +86 133 3619 4863

Conclusion

Large-diameter electromagnetic flowmeters are essential for modern water infrastructure. By selecting the right type and manufacturer, you can achieve:

- Accurate flow measurement in demanding environments

- Reduced operational downtime

- Compliance with industry standards