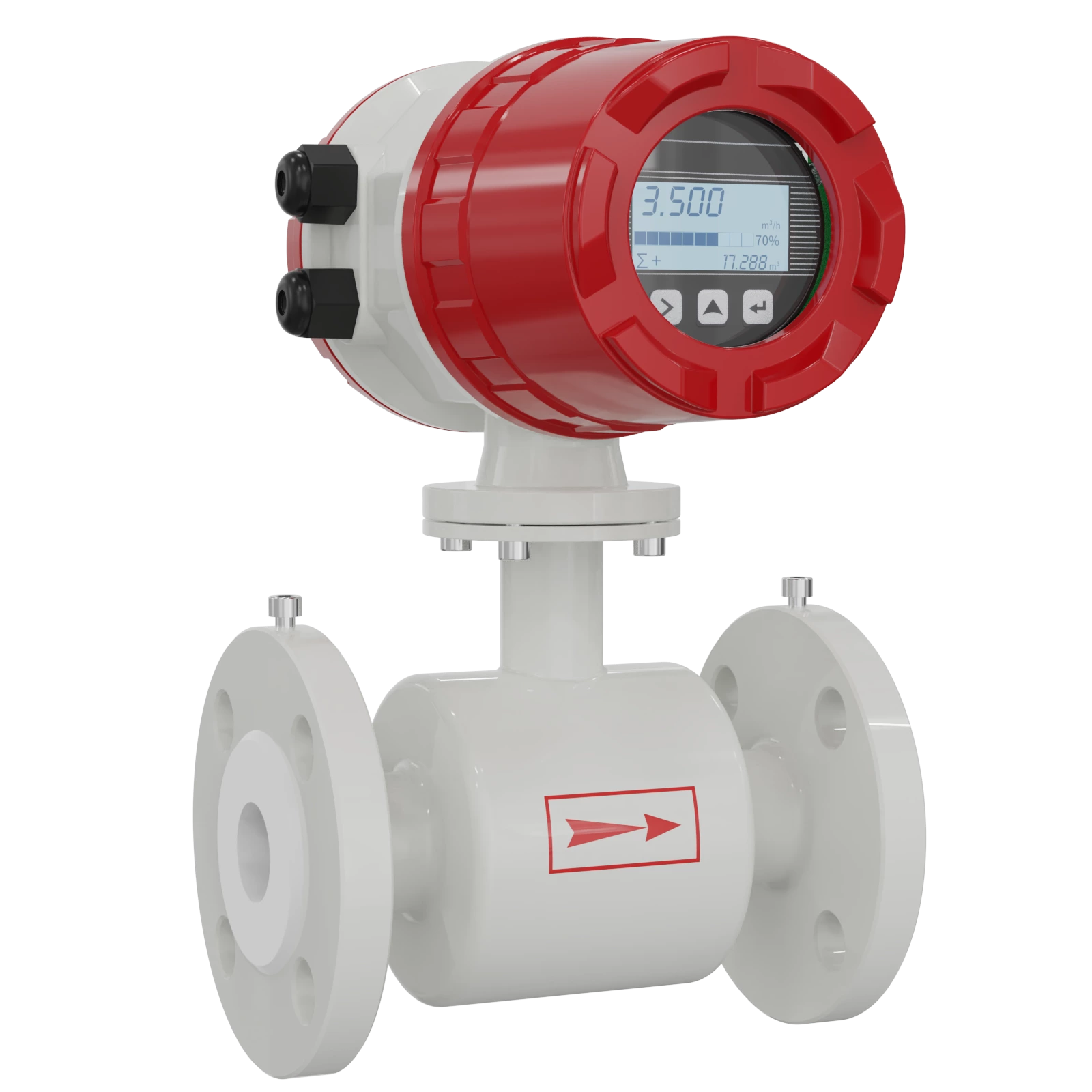

Electromagnetic Flowmeter for Cement Slurry

The Better Choice for Accurate Measurement

Accurate measurement of cement slurry is vital for industrial efficiency and quality control. Electromagnetic flowmeters stand out as the most reliable solution for this challenging application.

Why Choose an Electromagnetic Flowmeter for Cement Slurry?

Cement slurry is abrasive, conductive, and often contains particles, making it difficult to measure with standard flowmeters. Electromagnetic flowmeters excel here due to their:

- High Accuracy: Detects even small flow changes in slurries.

- Durability: Resists wear and corrosion from harsh materials.

- Minimal Maintenance: No moving parts to clog or wear out.

How Does an Electromagnetic Flowmeter Work?

Based on Faraday’s Law of Electromagnetic Induction, the process is simple and reliable:

- Magnetic Field Creation: Two coils generate a magnetic field inside the pipe.

- Voltage Induction: Conductive slurry flowing through the field creates a voltage.

- Measurement: Electrodes detect the voltage, calculating flow rate in real-time.

Key Features:

- A non-conductive liner (e.g., rubber, PTFE) isolates the fluid from the pipe, preventing interference.

- No moving parts means no clogging or mechanical wear.

Key Components of an Electromagnetic Flowmeter

Body Material

- Carbon Steel: Cost-effective for general use.

- Stainless Steel: Corrosion-resistant for aggressive conditions.

Liner Material

- Rubber (Neoprene/Polyurethane): Resists abrasion; polyurethane handles high-abrasion slurries.

- PTFE/PFA: Ideal for corrosive or highly abrasive media.

Electrodes

- Molybdenum Stainless Steel: Standard for most applications.

- Hastelloy/Titanium: For extreme corrosion resistance.

Why Electromagnetic Flowmeters Outperform Other Types

Vortex/Turbine Flowmeters: Struggle with slurry due to clogging and inaccurate readings in abrasive conditions.

Ultrasonic Flowmeters: Require clean fluid and cannot handle slurries with particles.

Electromagnetic Flowmeters:

- No Moving Parts: Reduces downtime and maintenance.

- Direct Measurement: Accurate even in high-viscosity slurries.

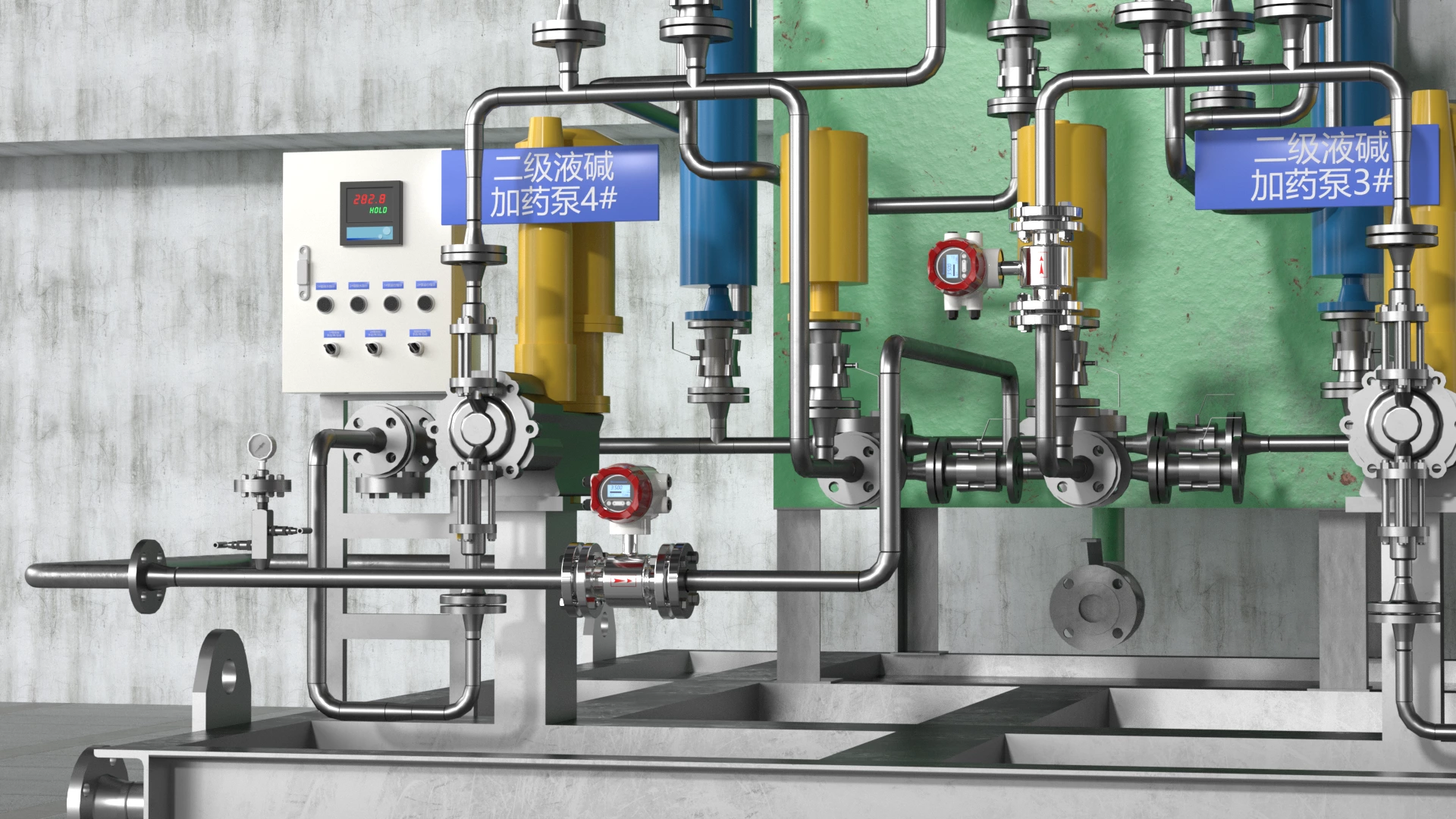

Applications in the Cement Industry

Cement Production Plants

Monitoring raw material mixing and slurry flow.

Concrete Batching Plants

Ensuring precise mix ratios for quality control.

Mining Operations

Measuring slurry transport in ore processing.

How to Choose a Reliable Manufacturer?

Select a supplier with expertise and local support:

Hangzhou Sinomeasure Automation Technology Co., Ltd. offers:

- 12+ Years of Experience: Specializing in cement slurry flowmeters.

- 23 Service Offices in China: Fast technical support and on-site assistance.

- Custom Solutions: Tailored to your plant’s specific requirements.

Get Your Solution Today

Why Trust Hangzhou Sinomeasure?

- 🏆 12+ Years of Experience in Cement Slurry Flowmeters

- 📍 23 Service Offices in China for Fast Support

- 🔧 Custom Solutions Tailored to Your Needs